SAND BLASTING ROOM

| Product Name | sand blasting room | ||

| Applied to wach material | casting, metal parts, profiles etc | ||

| Applicable industry | machinery, foundry, forging, mechanical and steel industry | ||

| function | production sand mould | ||

| Voltage | 380V/50HZ or 220V/60HZ | Warranty | One year |

| Power | Electricity | Certificate | CE, ISO 9001 |

| Model | Q26 | PLC | Siemens,Omron |

| Productivity | Customized | Low voltage | Schneider |

| Condition | New | Brands | Dongheng |

| Color | Customized | Size | Customized |

| Cleaning method | Automatic | Electrical control system | Auto-detection, auto-alarm and auto-cutout. |

| Material | Metal/coil | Origin | Shangdong, China |

| Cleaning material | Shot steel/shot grit/wire cut etc | After-sales service | Engineers available to service machinery |

| If you have any question or concerns. pls feel free to contact us. | |||

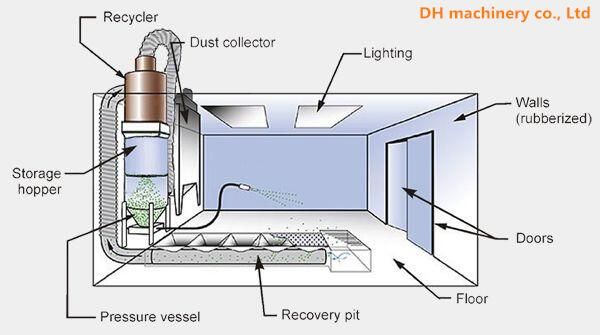

shotblasting chambers are designed for manual or automatic compressed air shotblasting of various work pieces, such as welded pieces, castings, forgings, railway wagons, containers, etc.

Work pieces are blasted in the chamber using compressed air that directs the blasting agent toward work pieces via a blasting nozzle. Then, a mixture of the blasting agent and residue falls into a trough, from where it is transported automatically to the elevator and air separator using scrapers and a transverse rotating worm. There, the blasting medium is purified, and after this it falls into a collection silo, ready to be used again. The shotblasting agent may be steel shot (round or granule), corundum, glass beads, etc.

CHARACTERISTICS:

●shotblasting chambers are designed for blasting work pieces of large dimensions and weights, and complex geometries

●The shot transport system using scrapers requires minimal foundation depth

●We provide a minimum level of dust in the chamber, since dust that is formed during the shotblasting procedure is removed using a cartridge dust collector, whereas fresh air enters the chamber through the ceiling

●The chamber may be equipped with a transport trolley or an overhead rail in the interior in order to manipulate work pieces

●A partial or full automation of the shotblasting procedure is possible using shotblasting robots

They are used in technologies, such as removal of rust, preparations for surface protection, matting, roughening, etc.

●There is a selection of chambers available with different sizes of work space and with numerous optional accessories which allow us to adjust our chambers to the needs of even the most demanding customer.

Qingdao Dongheng Foundry Machinery Co., Ltd., is a professional foundry casting equipment manufacturers, Located in the Lingang Industrial Park, Huangdao District of Qingdao City, here is the manufacturing base, complete industry categories, mechanical and electrical supporting the environment and strategic location, land and sea air transportation facilities.

Southern Cross Harbor Tunnel through the Qingdao Railway Station, north cross-sea bridge in-line near Qingdao Airport.Foundry Machinery Co.,Ltd. Qingdao Dongheng the existing staff of about"! 00 people, covering an area of nearly 40 acres, plant area of over 10,000 square meters, is a collection of scientific research, design, manufacture, installation and commissioning and technical advice as one of modern integrated machinery business.

Production of resin sand casting line, clay sand reclamation complete sets of equipment; V-process casting line, EPC modeling equipment; sand & shot blasting equipment; core shell machinery, core shooting machine, molding machine.

Complete sets of automatic molding line environmental protection equipment for casting enterprises to provide a full range of pre and post sales services.

TECHNICAL ADVANTAGES:

Qingdao Dongheng Foundry Machinery Co., Ltd. research strength is strong, long-term friendly relations of cooperation with major domestic research institutes, such as a hospital in Bengbu, Shanghai nine homes, Shenyang Institute of Electrical and the Luoyang four of Hospitals, Zhengzhou six homes, always keep up with the latest technology in the industry to comply with the "quality first, customer first" service approach, with new product design, development, prototype, debug capabilities, business, and technical staff time and up close, the user needs profound practical experience, each product an improvement are for user convenience, the interests of users. The spirit of "scientific, rigorous and efficient" style of work in the shortest possible time in accordance with the requirements to provide users with the best technical solutions, and delivery in the shortest period quality. Through a wide range of technical exchanges and cooperation, the introduction of foreign advanced technologies that will make my company's products to reach the domestic advanced level.The sand casting, molding line, shot blasting various aspects of senior experts in leading technology work, the experts have a wealth of experience and high technology of the industry, our company's product quality and technical content are at the forefront of the industry .

1.What is the target market for this machine ?

The Blaster is designed for customers who require a more sophisticated method than just manual cleaning in preparation for further processing or painting.

2.What type of abrasive media does it use ?

The Blaster is designed to use round steel shot. The shot is recycled inside the system and gets smaller and smaller during the blasting process, until it is completely consumed. Approximately two tons are required for start-up, and approximately 20 pounds are consumed per blasting hour. Replenishment is easily done as needed.

3.What utilities are needed to run the Blaster ?

The electrical system runs on three-phase input and a transformer will be provided for your supply voltage if required. Clean and dry compressed air supply is also needed.

4.What does it cost to operate ?

The highly efficient turbines require much less power that competitor's shot blast machines. Including abrasive consumption, power consumption and maintenance, the total operating cost averages around $20 per hour in US. When comparing this to your current methods, keep in mind that the Blaster is at least 4 to 5 times as productive as manual cleaning and only one operator is required to load and run the machine while it is working. Labor costs are much lower, plus you will have a huge amount of extra capacity for cleaning.

5.Are there any special operator skills required for the Shot Blaster ?

No, once the machine is installed and adjusted by our technician, running the machine consists of merely switching it on and setting the speed dial for the desired surface finish. Maintenance is simple too.

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.